Powered by 11.6-kW (15.5-hp)*, 675-cc (41.2-cu in.), air-cooled, V-twin, four-cycle gas engine

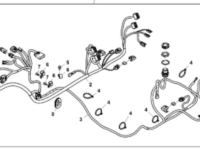

Engine (shield removed for illustration)

The Gator™ TH 6X4 Utility Vehicle is powered by an 11.6-kW (15.5-hp)*, 675-cc (41.2-cu in.), air-cooled, V-twin, four-cycle gas engine.

*The engine horsepower information is provided by the engine manufacturer to be used for comparison purposes only. The actual operating horsepower will be less.

Engine features

This engine has several performance and reliability features:

- Overhead valve design for greater efficiency and fuel economy

- Full-pressure lubrication system with standard filter

- Replaceable single-element air cleaner with remote intake

- Large-capacity spark-arresting muffler

- Electronic ignition for less service and fast, reliable starts

- Low fuel consumption and large 18.9 L (5 U.S. gal.) fuel tank

- Fuel consumption at half load and average speed is as follows:

Gator TH 6×4: 1.3 L/h (0.35 U.S. gph)

- Fuel consumption at half load and average speed is as follows:

- Engine is Environmental Protection Agency (EPA) compliant

Precision-engineered drive system optimizes hauling, towing, and hill-climbing capabilities

Gator TH 6X4 drive system

The Gator™ TH 6X4’s power is transmitted from the transaxle to the center axle. The rear axle is driven by roller chains from the center axle.

| 1. High flotation tires |

| 2. Transaxle |

| 3. Chain drive |

| 4. Engine |

| 5. Variable-speed drive |

Key elements of the drive system are as follows:

Variable-speed drive

The variable-speed drive consists of two clutches connected by a drive belt:

- Drive clutch is attached to and rotated by the engine.

- Driven clutch is attached to and drives the transaxle.

Features include:

- Infinite selection of speeds (0 km/h to 32 km/h [0 mph to 20 mph])

- No shifting necessary as operator increases speed

- Adjusts speed to the load to avoid bogging down when going up a hill or through challenging conditions because the wrong gear was selected

Variable-speed drive

| 1. Idle speed |

| 2. Moderate speed |

| 3. High speed |

| 4. Drive clutch |

| 5. Driven clutch |

Here is how the variable-speed drive works:

- As the engine speed increases, the spring-loaded drive clutch is closed by weights being forced out by centrifugal force.

- As the drive clutch closes, the belt rides up to the largest diameter of the drive clutch and forces open the driven clutch.

- With the belt running in the smallest diameter of the driven clutch, the speed being transferred to the transaxle is increased.

- The driven clutch is designed to sense varying loads (inclines, mud, etc.) and constantly adjusts the drive speed upward or downward, so the engine rpm remains constant at constant throttle position.

Transaxle

The transaxle is fully enclosed and runs in oil for reliability.

Helical gears are used for quiet operation.

The differential design reduces scuffing of the turf during turns because the inside wheels turn slower than the outside wheels (vehicles that have a solid axle shaft must skid the inside wheel when making a turn).

Traction assist (differential lock) is built into the transaxle:

- Allows locking the rear drive wheels together

- Provides increased traction in tough spots

The neutral start safety interlock is provided for the engine ignition system.

Bolt-on cast-aluminum rear axle housings provide an extremely strong supporting structure.

- Large, sealed bearings are located inside the housing for better protection

- Forged-splined shaft for increased torsional strength

Features operating conveniences such as high-back seats, cup holders, 12-V outlet, glove box, and fuel gauge

Side-by-side bucket seating

Numerous features offer the operator and passenger a comfortable ride and provide many operating conveniences.

- Side-by-side bucket seating provides room for one operator and one passenger

- Hip restraints serve as a handhold and help to keep the operator and passenger in their seats over rough terrain

- Both seats tilt forward for dry storage and ease of service

- Choice of adjustable or non-adjustable driver’s seat

- Hour-meter is standard to assist in maintaining regular service intervals

- Integrated cupholders

- 12-V outlet located on instrument panel

Convenient walk-through operator station

The control location and walk-through platform provide easy entry/exit for operator and passenger.

NOTE: Shown above with the optional front bumper, brush guard, front fender guard, and floor mat.

NOTE: The front bumper is standard on the Gator™ TH 6X4 Diesel.

- All models feature a park brake indicator light, hour-meter, and tank-mounted fuel gauge as standard equipment

- Traction assist (differential lock) is hand operated and conveniently located between the operator and passenger seats

- Traction assist indicator light (Gator TH 6X4 only)

- Glove box is located in the dash to provide a convenient storage area for small tools and the operator’s manual

- Grab bar is provided for the passenger

- Center-mounted key switch

- Additional storage is provided between the seats

Durable deluxe cargo box is spacious and allows for easy loading and unloading

Deluxe cargo box (TX 4X2 shown)

Deluxe cargo box, tailgate lowered (TX 4X2 shown)

The deluxe cargo box side panels and tailgate consist of a 15 percent glass-filled polypropylene composite material that eliminates rust and dents and reduces noise. The cargo box floor and load guard (front panel) are made of steel.

Deluxe cargo box tailgate

Tailgate handle

Tailgate lowered to 150 degrees

The tailgate can be opened or removed for easier cleanout and to carry longer items. The tailgate features a truck-like latch, and can be operated with one hand.

The standard installed lanyards can also be removed to lower the tailgate to 150 degrees for convenient loading and unloading tasks.

Deluxe cargo box tilt

Integrated handle (B) and latch (A)

Gas assist (C) and prop rod (D)

The deluxe cargo box is easier to latch (A), unlatch, raise, and lower with the integrated handle design (B) and gas assist (C).

A prop rod (D) is provided to hold the box in the upright position for operator convenience, as well as limit box pivot travel.

Integrated tie-down points

Integrated tie-down point in cargo box bed

Additional tie-down points on cargo box

The deluxe cargo box offers integrated tie-down points for increased versatility. Tie-down points are located in the following areas:

- Four corners inside the cargo box bed

- Four points on the load guard directly behind the operator station (A)

- Tie-down bars on either side of the cargo box (B)

- Six points on the underside of the cargo box frame (circled)

Converting deluxe cargo box to a flat bed

Deluxe cargo box converted to a flat bed

The deluxe cargo box easily converts to a flat bed by removing ten bolts and unplugging rear lights (if equipped) at the harness pigtail at the rear of the machine. The flatbed configuration allows loading irregularly shaped cargo.

Optional accessories

Brake and taillight

Bedmat—protects the steel floor from dents

Optional accessories for the deluxe cargo box include:

- Factory-installed brake and taillight

- Brake and taillight only (for back-up lights, flashers and turn signals, order deluxe light kit)

- Factory-installed spray-in liner (not shown)

- Improves skid resistance and surface abrasion protection

- Cargo box bed mat

- Cargo box power lift (not shown)

Specifications

|

Box capacity |

|

| Volume |

465 cu L |

| Weight TH 6X4 gas |

454 kg (1000 lb) |

| Weight TH 6X4 diesel |

550 kg (1200 lb) |

|

Box dump angles (degrees) |

|

| Manual dump |

43 degrees +/-1 |

| Power dump |

43 degrees +/-1 |

|

Cargo box load height |

|

63.5 cm (25 in.) |

The cargo box load height allows for easy loading and unloading.

CAUTION: Carrying extra-long cargo that extends beyond the box can adversely affect stability.