Accurately apply low-rate herbicide and high-rate fertilizer with a single machine

LS475 applying in the field

During the busy spring season, you need to complete jobs as crops are planted, from applying high-rate fertilizer on unplanted corn fields to low-rate pre-emergent herbicide on soybeans. Dual centrifugal solution pumps with dedicated magnetic flow meters work together to achieve pin-point rate accuracy through the entire flow range between 18.9 and 1589.9 L/min (5 and 420 gpm).

Dual pumps enable you to apply:

- High rates at higher speeds without sacrificing tank agitation. For example, this system can apply 378.5 L (100 gal.) per acre at speeds over 32.2 km/h (20 mph). Applying at faster speeds means more acres covered per hour, and duals pumps give operators the ability to apply more product per acre.

NOTE: Application rates can be impacted by solution density, nozzle size, and tip pressure.

- A wide range of rates with the same machine, increasing machine capability and improving asset utilization. For example, apply 32 percent fertilizer at a rate of 302.8 L (80 gal.) per acre, then move to the next field and spray glyphosate with 37.85 L (10 gal.) of carrier per acre – all by simply capping the cam-lock tips and rotating high-flow nozzle bodies.

Solution pumps are common components with self-propelled sprayers and use flange-face fittings instead of pipe threading for easy maintenance.

Magnetic flow meters:

- Have no wear parts, reducing downtime

- Are accurate through a wider range than turbine flow meters

- Are compatible with suspended fertilizer solutions

Cover more acres between refills with the large solution and rinse tanks

LS475 solution and rinse tanks

With higher-speed planting, the season is becoming more condensed every year. When you need to get acres covered, getting tender trucks back to the plant increases productivity. To hold more product onboard, the LS475 solution system features a stainless steel 7570.8-L (2000-gal.) solution tank and black poly 757.1-L (200-gal.) rinse tank.

The large solution tank allows operators to cover more acres between refills. This tank gets tender trucks empty faster and back on the road, translating into less idle time for the tender truck and you and quicker load turn-arounds.

The industry’s largest rinse tank provides more onboard fresh water for:

- Triple rinsing the solution tank with the automated rinse cycle

- Flushing the boom plumbing

- Container and eductor bowl rinsing

- Optional on-board hydraulically powered pressure washer

The light-blocking black poly material discourages algae growth in the rinse tank.

Cover 12 percent more acres per pass using the widest factory-installed boom

LS475 boom

You want the least amount of machine traffic in their fields, and the wide LS475 boom allows ag service providers to cover more acres per pass, reducing the amount of total passes.

The time-proven 27.4-m (90-ft) 4 Series Sprayer steel boom unlocks reliable productivity for ag service providers. This durable boom features:

- Full-boom breakaway

- Tri-direction boom-tip breakaway

- Auto-fold

The standard dual plumbing system features 76.2-cm (30-in.) off-center high-flow nozzle bodies (turrets) and a 152.4-icm (60-in.) on-center cam-lock. When configured for 152.4-cm (60-in.) cam-lock spacing, the effective spray pattern is 29 m (95 ft). The 76.2-cm (30-in.) nozzle body configuration achieves a 27.4-m (90-ft) spray pattern.

With 152.4-cm (60-in.) high-flow cam-lock plumbing, you cover 12 percent more acres per pass compared to the largest competitor boom width at 25.9 m (85 ft). Make fewer passes through the field and reduce compaction, as well as time spent spraying, with this boom.

You can easily switch from low-pressure/high-rate fertilizer application to high-pressure/low-rate for pre-emergent herbicide, burn-down, or pasture application. This dual plumbing eliminates the need for you to route additional plumbing lines and connections.

Seven-section boom control:

- Reduces overlaps

- Minimizes wasted product

- Improves quality of application

Utilize John Deere Section Control software for an automated application experience.

Auto-fold allows the boom to automatically unfold and fold faster, getting operators in and out of the field quicker, and the low-profile, flat-fold design delivers superior transport visibility.

Fast, clean, automated tank filling enabled by technology

LS475 load system keypad

When the tank is empty, every second counts trying to get back into the field. PowrSpray features independent fill and spray circuits with dedicated pumps to maximize flow. The dedicated self-priming transfer pump can fill the solution tank at over 1135.6 L/min (300 gpm). This PowrSpray system can:

- Automatically fill to a predefined tank level while automatically adjusting engine speed

- Pull fresh water from the rinse tank to clean the fill system

- Be manually reduced if a slower fill rate is desired

- Pause filling, giving you sufficient time to add ingredients and rinse containers

- Allow for quick and easy operation at the load station for all skill levels

The 12-button keypad enables complete automation, reducing the need for you to turn multiple ball valves. The features include:

- Fill station light on/off (button 1)

- Rinse water source for transfer pump (button 2)

- Menu/numeric input (button 3)

- Agitation (button 4)

- Pressure washer (button 5)

- Automated rinse cycle (button 6)

- Eductor/container rinsing with solution pump (button 7)

- Eductor/container rinsing with transfer pump (button 8)

- Eductor on/off (button 9)

- Push-on target fill (button 10)

- Push-on manual fill (button 11)

- Pull-on target fill (button 12)

- Pump speed increase/decrease (via manual hydraulic valve)

LS475 load station with keypad

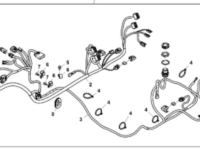

John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions

Connected Support technology

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink™ telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:

- Keeps you running by monitoring machine health and promptly alerting you and your dealer of issues

- Saves time by remotely viewing in-cab displays, reducing trips to the machine

- Reduces or even eliminates technician trips to a machine through remote diagnostic and remote software reprogramming capabilities

- Connects experts with the information needed to respond to downtime faster and prevent it altogether

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.