Two available sizes for a 700D factory-installed center feed drum improves feeding of crop into the combine feederhouse

The center feed drum is designed for efficient and consistent feeding of the crop into the combine feederhouse. Beginning with model year 2020 700D Draper Platforms, customers will have the ability to choose between a 356-mm (14-in.) or 406-mm (16-in.) center feed drum to be factory installed.

Feature benefit:

- 356-mm (14-in.) or 406-mm (16-in.) diameter factory-installed feed drum significantly improves feeding of the crop

- Strategic location improves crop handling and capacity, increasing productivity in high-volume crops such as irrigated wheat, barley, or canola

- Combine performance is improved due to retractable fingers that enable smoother feeding

- Capacity increase in tough conditions by 20 percent due to an upgraded center feed section slip clutch

Center feed drum

Feed drum retractable auger finger

Functionality:

The feed drum protrudes forward from the draper back sheets, improving the crop handoff from the draper side belts. An increase in slip clutch torque of the center feed drum from 1200 Nm to 1650 Nm allows for increased capacity in tough crop conditions

In some crop conditions, crop can hesitate at the corners of the feed drum but the retractable drum fingers keep the crop moving into the combine.

Takes one person a few minutes to convert draper from field to transport without use of tools

The 730D, 735D, and 740D Draper models can be equipped with an integrated, slow-speed transport system.

John Deere value:

-

Need for a header trailer is eliminated due to dual-front dolly wheel tires with an extendable tongue and two-gauge wheel tires that can carry the complete weight of the draper when in transport

-

Road transport is quicker and easier because one person can convert the draper from field to transport mode in a few minutes without the use of tools

Theory of operation

In field mode, the dual wheels become the left- and right-hand gauge wheels. For transport, the left-hand dual-dolly wheels support one side of the draper frame and the right-hand dual wheels are repositioned to support the right-hand end of the frame.

The transport package includes warning lights, which can be plugged into a seven-way power source for road transport with a 32.2-km/h (20-mph) speed limit for farm equipment transport.

Dual-wheel arm and single-wheel arm assembly

Slow-speed transport – rear wheels

NOTE: The 730D, 735D, and 740D Drapers are equipped with two ST215/75R14 gauge wheel tires as base equipment and four ST215/75D14 gauge wheels with the low-speed transport option.

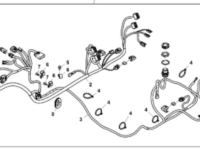

Dual-knife drive system is timed

Cutterbar epicyclical gearcase

Knife drive shaft

The unique dual-knife drive system is timed, creating the smoothest-possible reciprocating knife-drive system currently in the industry. The positive, reliable shaft-driven dual epicyclical in-line knife drives with built-in driveline protection, provide operators with the strongest knife-drive system.

Double-cut knife system produces a cleaner cut

All John Deere 700D Drapers include a double-cut knife which features a hydraulic tilt that is controlled from inside the cab. All 10.6-m (35-ft) and 12.1-m (40-ft) draper cutterbars have knifeback reinforcement straps to strengthen the knifeback.

Feature benefit:

- Maximized productivity through longer stroke of knife section provides a faster, cleaner, and smoother cut, which allows operators to harvest at faster ground speeds

- Productivity is maximized in tough conditions through a reinforced knifeback that strengthens the cutterbar

- Reduced cost of operation and increased wear life with hardened sickle sections and unique boron treatment

- Hydraulic tilt optimizes the cutterbar angle for varying conditions, extending the harvest day and providing the lowest-possible cut height

Double-cut cutterbar system

Double-cut rock guard

Functionality

The 100-mm (4-in.) cutting action produces a cleaner cut versus the tearing effect of shorter-stroke cutting systems. Knife hold-downs are easily adjusted to help maintain harvesting performance.

Tilt cylinder

The cutterbar hydraulic tilt adjusts a full 8 degrees while maintaining excellent visibility to the cutterbar throughout the tilt range. For improved ease of use, the hydro handle can be configured to control the platform tilt.

Reel resume and reverse are features on the 700D Drapers

Reel resume and reverse are features on the 700D Drapers. The combine operator can store two different reel positions with one setting for normal conditions and another for down, tangled, short, or leaning crops.

Feature benefit:

- Added time savings and convenience with saved reel positions, lowering operator fatigue

- Increased harvest efficiency through a reel-reverse feature which reverses the reel in conjunction with the center feed drum and belt to back outplugs

Draper drum

Draper reel